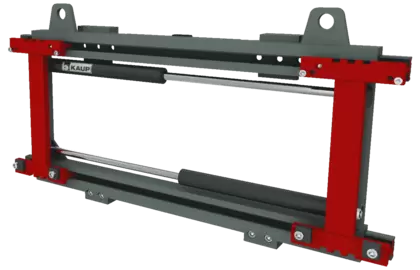

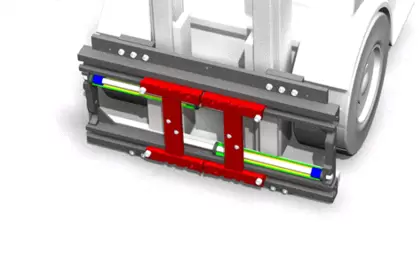

Rotating Fork Positioner foundry version T456ZG

Select model and request

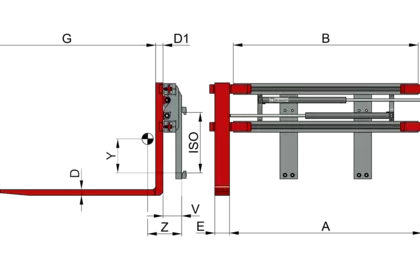

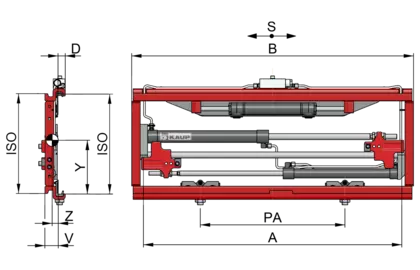

Specification:

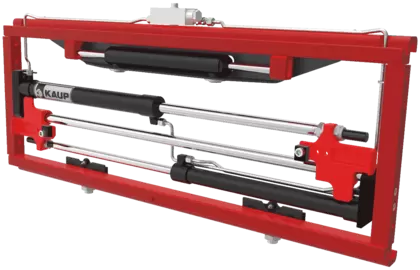

The design is, in principle, the same as the normal T456BZ version, the foundry version of this attachment range is suitable for applications with extremely high working temperatures as found, for example, in steel works. Compared to the T456BZ, the KAUP Rotating Fork Positioner T456ZG has a closed front plate and basic plate as well as heat resistant coated hydraulic pipes.

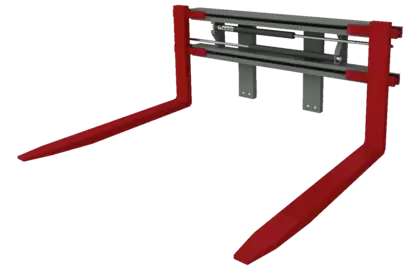

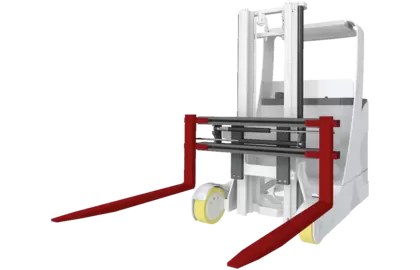

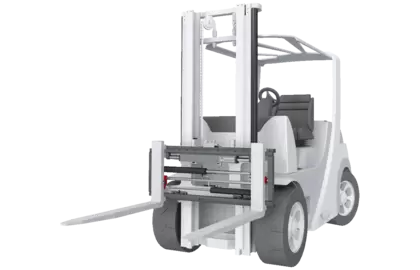

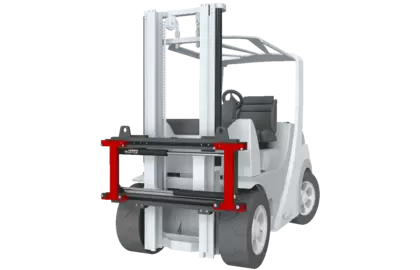

Product pictures and videos

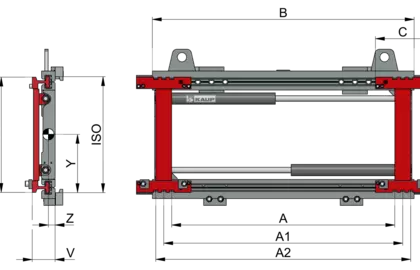

Product details

Qualities:

- Attachment also available with screw-on forks

- Solid construction

- Rotation 360° endless

- Optionally available with sideshift

- Larger models and construction widths optionally available

- Md: Torque at dP = 125 bar.

- Larger models and different widths available upon request.

- Also available with bolt-on forks:T456ZGA

- Also available with sideshift, model T496ZG on request

Technical data

Rotation 360° continuous - 2 hydraulic functions

Downloads & Tools

Calculate residual capacity

Do you want to equip your forklift truck with an attachment from KAUP? Then you can calculate the residual capacity of your forklift roughly and without obligation here.

Create online offer

With our eQuotation-Tool you can independently create a binding offer for an attachment from KAUP.

Please login to use the eQuotation-Tool.

We are here for you.

We offer you first-class services for our quality attachments: whether spare parts, professional technicians for repair and maintenance on site, training for regular care and ongoing maintenance of KAUP products.